Mustard is a staple in our kitchens. From the tables of the Romans to the shelves of our supermarkets, it has endured through the ages, retaining its unique character and ability to enhance dishes.

Originating in Central Asia, where mustard seeds grew wild, this condiment has gradually found its way into every culinary culture. The Romans were among the first to mix ground mustard seeds with grape must - giving rise to the term “mustum ardens” (fiery must), which later became “mustard”.

In the Middle Ages, the city of Dijon established itself as the mustard capital of the world, developing a unique know-how that has earned it international renown to this day.

Today, mustard occupies a special place in the world's gastronomy, from traditional French cuisine to American hot dogs and Indian curries. Although industrialized, its manufacture remains a complex process, requiring expertise and precision to obtain the unctuous paste with its subtle yet piquant notes that characterize this ancestral condiment.

The basic ingredients

The basic ingredients of mustard are relatively simple, but their quality and proportions are essential to obtain an excellent end product.

Mustard seeds are the main ingredient, and come in three main varieties:

- Black mustard seed (Brassica nigra): the most pungent of the three, it is particularly prized in the manufacture of Dijon mustard. Its powerful taste and complex aromatic notes make it a choice ingredient for traditional mustards.

- Brown mustard seed (Brassica juncea): less strong than black but more fragrant, it is widely used in Indian cuisine and in some European mustards. It offers an excellent balance between heat and aroma.

- White mustard seed (Sinapis alba): the mildest of the three, it is often used in English and American sweet mustards. It provides a creamy texture and moderate spiciness.

The base liquid is just as crucial:

- Vinegar, traditionally white wine for Dijon mustard, plays a dual role: it activates the pungent compounds in the seeds and ensures the product's preservation. Its quality directly influences the final taste.

- Verjuice (green grape juice) is sometimes used in traditional recipes.

- Water is also used, particularly in milder mustards. Other ingredients that complete the recipe:

- Salt, indispensable for enhancing flavors and helping to preserve them * White wine, which adds complexity and finesse (particularly in Dijon mustard) * Spices and aromatics: depending on the recipe, turmeric, paprika, aromatic herbs, garlic, etc. may be used.

Some manufacturers add natural stabilizers such as xanthan gum to improve texture.

The industrial manufacturing process

The industrial production of mustard follows a rigorous process that begins with two crucial stages:

Seed selection and cleaning

Mustard seeds generally arrive in bulk at the manufacturers, who first carry out meticulous quality control. Sophisticated machines equipped with vibrating sieves and optical systems examine each batch to:

- Eliminate foreign bodies (stones, plant debris, other seeds) * Discard damaged or non-conforming seeds

- Check moisture content, which must be optimal * Check seed size and color to ensure homogeneity

Soaking and preparation

Once cleaned, the seeds undergo an essential soaking phase:

- The seeds are immersed in a mixture of vinegar and water for 8 to 12 hours.

- This step rehydrates the seeds and activates their natural enzymes.

- The temperature and duration of soaking are precisely controlled, as they directly influence the final taste.

- The soaking liquid is sometimes flavored with white wine or spices, depending on the recipe.

- By the end of the soaking process, the seeds have swollen and become softer, ready for the next stage of grinding.

Grinding the seeds is a key stage in giving mustard its characteristic texture:

- The soaked seeds are fed into special industrial grinders with granite or stainless steel grinding wheels.

- The speed of rotation is carefully controlled to avoid overheating, which could alter organoleptic properties.

Depending on the type of mustard required, grinding can be more or less fine:

- Very fine for classic Dijon mustard

- Coarser for “à l'ancienne” mustard, in which the seeds are partially crushed.

The next step is to blend the ingredients:

- The paste obtained after grinding is transferred to mixing tanks.

- The other ingredients are added progressively according to the recipe: additional vinegar, salt, spices, wine...

- Mixing is carried out under vacuum to prevent oxidation

- The temperature is kept constant to preserve the aromas. This phase can last several hours to obtain a perfect emulsion.

The final stage is refining and maturing:

- The mustard is stored in vats for several days (up to two weeks). This period allows the flavors to develop and harmonize.

- The temperature is kept constant at around 20°C.

- Regular checks are carried out to monitor product development.

- Once maturation is complete, the mustard is packaged in glass or plastic jars.

The different varieties of mustard

The different varieties of mustard constitute a rich gastronomic heritage that has developed over the centuries:

The mustard of Dijon

True emblem of the French gastronomy, it is elaborated according to an ancestral know-how that goes back to the Middle Ages . Its unique recipe combines finely ground black or brown mustard seeds with white vinegar, creating this characteristic creamy texture. Its powerful and refined taste comes from a meticulous manufacturing process where the grinding temperature is precisely controlled. It is traditionally used to accompany cold meats, but also in the kitchen to tie sauces and enhance vinaigrettes. Discover the excellence of Pommery® Dijon Mustard, made according to tradition. It is a fine, delicate mustard, forever classic, and an essential in French cuisine.

Old-fashioned mustard

This variety is distinguished by its unique manufacturing process where the seeds are deliberately left partially whole . Coarser grinding preserves the integrity of the seeds, creating a granular texture that adds character to dishes. Its more round and less aggressive taste than the traditional Dijon allows you to discover all the aromatic richness of mustard seeds . It is particularly popular in the kitchen for its ability to add relief to stews and sauces. Its distinctive texture makes it a condiment of choice for marinades and meat crusts. Let yourself be seduced by Moutarde à l'Ancienne Petits Gourmets®, the perfect companion for your kitchen. Its authentic taste and generous texture will enhance your grilled meats and simmering dishes. Its composition is similar to our famous Meaux® Pommery® Mustard.

Flavoured mustard

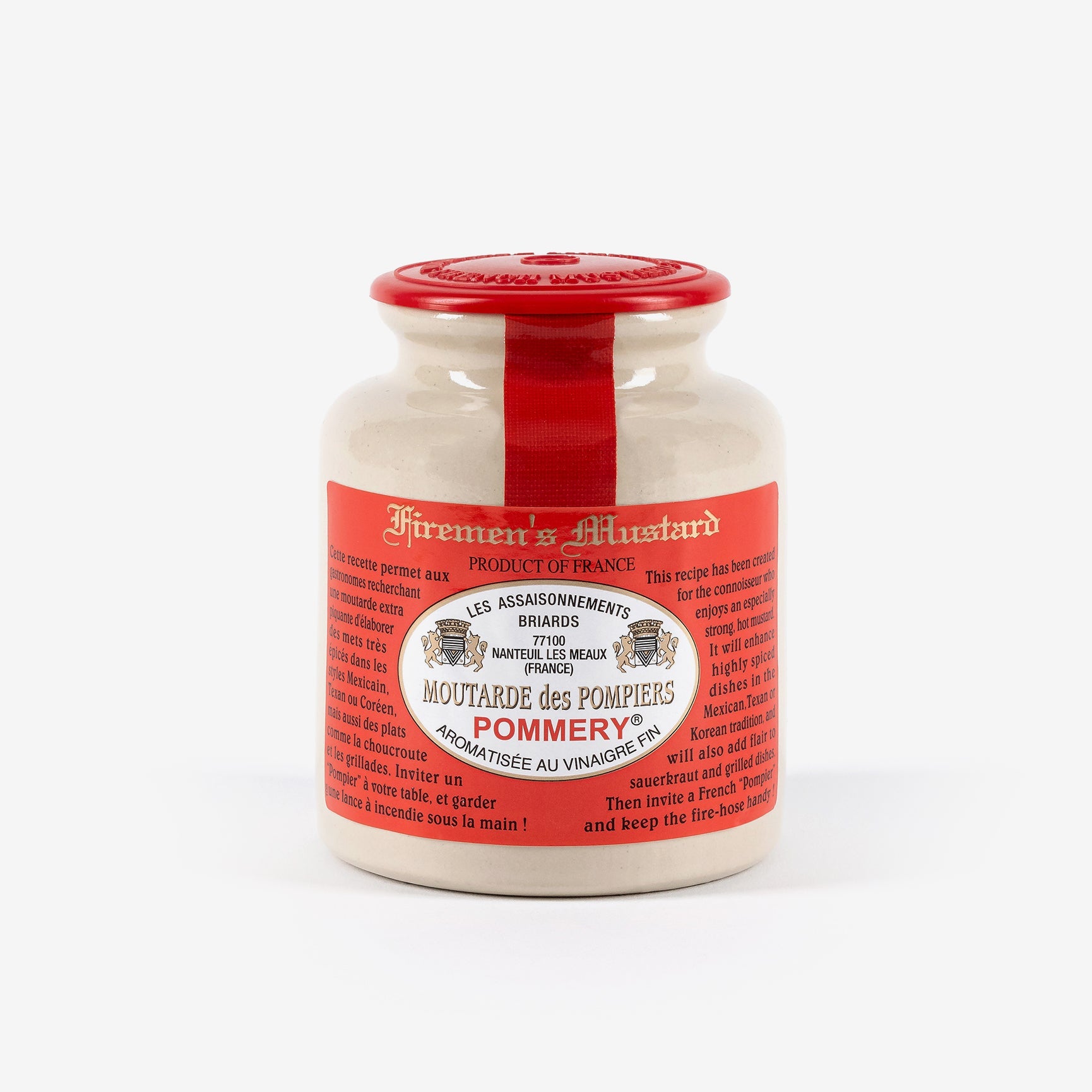

These modern creations combine the traditional strength of mustard with noble ingredients and sought-after flavours. Each variety is the result of a long research to create harmonious associations. The process of aromatization is crucial: ingredients are incorporated at specific times during manufacture to preserve their qualities . These mustards make it easy to create sophisticated sauces and bring a touch of originality to classic dishes. The range of flavoured mustards from Briards Seasonings ranges from sweet flavours (honey, fine herbs) to more intense notes (truffle, cognac). Explore the collection of Pommery® Mustards, true gems of culinary creativity. Each of our recipes is an invitation to discover unique flavors.

Regional specialities

Each French region has developed its own recipes, reflecting its terroir and culinary traditions. The variations concern the choice of seeds, the nature of the vinegar used and the local spices incorporated. These mustards reflect the diversity of French gastronomic heritage and the creativity of regional moutards. Some recipes are protected by quality labels that guarantee their authenticity . These specialties are often produced in small series to preserve their artisanal character. These different varieties illustrate the wealth of the French cheese-making heritage and the constant innovation of manufacturers to offer exceptional products.

Quality control and conservation

Quality control and conservation are fundamental aspects in mustard production, guaranteeing both food safety and the preservation of taste qualities.

Manufacturing standards:

- Regular microbiological checks at each stage of production

- Systematic verification of the quality of incoming raw materials

- Daily organoleptic tests by tasting panels * Complete traceability from seed to finished product

The packaging:

- Use of specially designed containers (glass, stoneware or food-grade plastic)

- Automated vacuum filling process to avoid oxidation

- Control of filling level and crimping of lids

Labelling according to European standards with:

- The detailed composition

- The expiry date

- The batch number

- The conditions of storage

Shelf life:

- Well-prepared mustard usually lasts 18 to 24 months

- Vinegar and salt act as natural preservatives

- The shelf life takes into account a safety margin

- Taste qualities are optimal in the first 12 months

Storage conditions:

- Ideal for storage at room temperature (between 10 and 20°C)

- Avoid direct exposure to light

- Keep the jar tightly closed after opening

- Store in a dry place to avoid condensation

Once opened, preferably keep in the refrigerator to maintain taste qualities.

What about today?

The manufacture of mustard, although industrialized today, remains an art that combines tradition and modernity. This thousand-year-old condiment has survived through the ages, maintaining its authenticity while adapting to contemporary production and food safety requirements.

The evolution of manufacturing methods reflects a constant search for excellence. Modern production techniques, combined with rigorous quality control, now make it possible to produce high-quality mustards on a large scale, while preserving the characteristics that make this condiment famous. Les Assaisonnement Briards perpetuates this ancestral know-how while innovating to meet consumer expectations.

Current trends show a renewed interest in artisanal mustard and innovative recipes. Consumers are becoming more and more knowledgeable, looking for authentic products and original flavors. This demand stimulates the creativity of moutardiers who develop new recipes while respecting traditional methods.

The future of mustard looks promising, driven by a subtle balance between respect for traditions and innovation. The challenges of sustainability and local raw materials supply are at the heart of the concerns of manufacturers, who are committed to a responsible production approach. The mustard continues to write its history, remaining more than ever an essential element of our gastronomic heritage.